Wood Lounge Chairs With Rounded Corners to the Arms by Restoration Hardware

Bernacki & Assembly, Inc.

Eames Lounge Chair Set (670/671) Restoration

The Chair of the Century and Its Challenges

The usually called Eames Lounge Chair prepare (670/671) was introduced in 1956 and has been since one of the most pregnant furniture designs of the 20th century. Engineered by the American design couple Charles and Ray Eames, the ready is often chosen "the chair of the century" and is nevertheless received with enthusiasm for the beauty of the blueprint and infrequent comfort.

The Chair's modern condolement comes not only from the way the headrest, the backrest, and the seat are ergonomically fashioned, but as well from the unprecedented combination of the other components. The soft filled cushions finished in black leather with button tufting and the rocking connectedness organisation fitted with flexing daze mounts make the luxury complete.

From the fabrication perspective, the famous chair combines modern technology with intricate traditional hand craftsmanship. The signature curved plywood components are made of several layers of glued together woods veneer and shaped under loftier force per unit area in industrial molding press. After the basic molds are fabricated, the excess wood is trimmed to the desired shapes and the edges are smoothed. The plywood parts are then treated with a cease that enhances the depth of the outer veneer woods grain.

The original version made by Herman Miller in the mid-1950s used Brazilian rosewood veneer which was discontinued in the early 1990s. Still in production, Herman Miller uses veneers of carmine, walnut, Palisander rosewood (a sustainably grown woods with similar grain patterns to the original Brazilian versions), and other finishes. The original cushions were made of soft leather and plush down feathers similar to more traditional upholstered chair styles, despite its mod design. In 1960, a combination of cream padding was added to the down. The modern cushions are at present padded with foam and Dacron.

Iconic for their comfort and pattern, many chairs are even so in use today. As with any functional object, components can tend to vesture out over time. Even though the set is yet in production, not all the components are compatible to facilitate partial replacement.

Eames Lounge Chair Set (670/671) later on conservation

Given the subtle changes in fabrication over the years; treatment to ensure their continued functionality while retaining their historic integrity, yields unique challenges and considerations.

The post-obit are iv examples of by treatments for this iconic model.

#1

Condition consistent with historic use

(Treatment of original upholstery)

Eames Lounge Chair as seen earlier conservation

The same chair after treatment

Status

The chair arrived missing the metal riser at base. The veneer was selectively delaminating with related areas of loss on both the chair and ottoman. The terminate was well worn, with a dull luster. The leather was dry and croaky, with tears, and loss at left and correct-side armrest, and welt. The zipper was compromised. The cushion had lost support and shape. Leather was dry and croaky on seat cushions.

TREATMENT

The absorber panels were removed from frame of the seat and ottoman. All of the surfaces of the chair were cleaned. The delaminated veneer was consolidated, and loss areas infilled with comparable forest species sympathetic in tone and grain. A new Herman Miller Eames chair riser was installed on base.

Surface imperfections were locally addressed and infills retouched and integrated. The surface was polished and waxed, hand buffed to a compatible sheen. The support was reconditioned, the down added in all cushions to restore shape and feel. The torn and or worn sections of leather and welting were mended. The leather was cleaned and conditioned. The studio worked with Herman Miller to replace the cushion zipper and back back up.

Eames chair item earlier treatment with visible damage to welting

After the treatment of welting, leather, and finish

#2

Condition consequent with historic utilise

(Herman Miller replacement of upholstery)

Condition

The metal base arrived dingy with scratches and corrosion. The wood frame sustained damage from water exposure with related areas of discoloration and impairment to the cease. The decorative veneer had areas of delamination and related areas of loss. The outer edges of the wood elements were abraded with gouges. The leather upholstery was well worn with related tears, cracks, abrasion and grime. The attachment of the upholstered components was loose due to the corrosion of the hardware.

Treatment

The metal base was surface cleaned, the corrosion addressed and the scratches on the black cease base were retouched. The delaminating veneer was consolidated, losses infilled with a species matching in grain and tone. The oxidized terminate was saturated, and areas in the finish were retouched and integrated where necessary. The treatment of the upholstery and metal attachments was completed by the manufacturer. Leather samples were provided for customer's approval.

In a higher place: During treatment photos show the disassembled upholstery components in preparation for collaboration with Herman Miller.

Before

Later on

Before

After

Before

Subsequently

Earlier

Afterward

Earlier

Later on

#three

Replacement of cleaved back rest and treatment of original upholstery

Status

The chair arrived at the studio in two parts due to a full suspension in the back rest. The arm pad was detached from the back rest on the side. The proper right-side flexing shock mount was cleaved. The seat and head rest panel were in good structural condition. The woods elements had pocket-size imperfections, gouges, chipped veneer, scratches with various sizes, forth with small discoloration. The leather upholstery (cushions and arm pads) had some evidence of clothing and cracking with minor imperfections such as in-prints and scratches. All metallic parts (base and back braces) had like evidence of wearable as the other components.

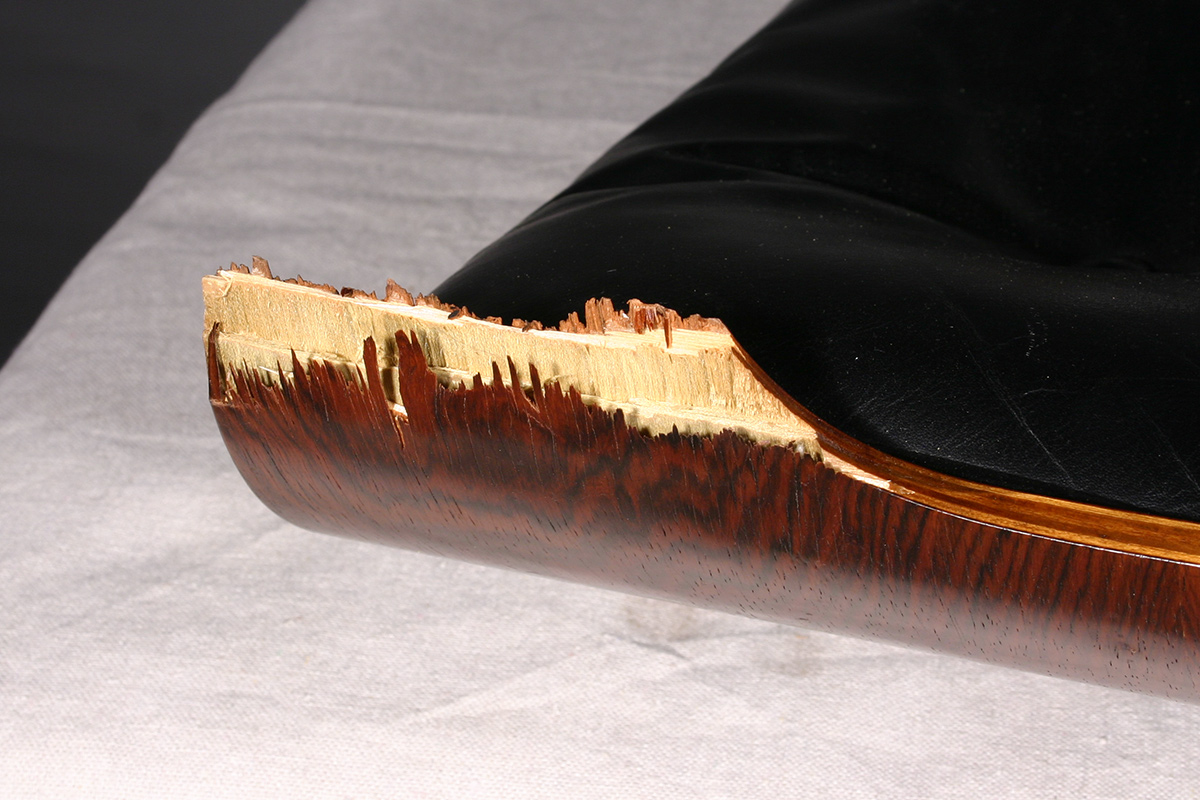

Impairment to Eames chair bent plywood component

TREATMENT

Unlike solid forest piece of furniture, broken bent plywood parts could not be satisfactorily addressed with woods infills. The unabridged component must exist replaced in club to ensure stability. Any endeavour to repair the existing break in the chair panels would have rendered the chair every bit extremely delicate and utilize of the chair would have non been recommended. Given the celebrated Rosewood end of the original panels, it was not possible to club simply one new plywood panel to match the remaining panels. It was adamant that the part must be ordered in a dissimilar veneer and then re-veneered in rosewood and treated for color to match the remaining panels. Given the cost involved, the client decided to go on with a more cost-constructive treatment, in which all of the plywood elements were ordered from Herman Miller and they were not re-veneered. The client was satisfied with the new look of wooden elements in the combination with existing upholstery.

Restored Eames Lounge Chair - new bent plywood parts fabricated by Herman Miller

#4

Treatment of all components

CONDITION

The following chair was damaged as a upshot of a ceiling collapse. The chair was broken in two parts with the seat section disconnected from the dorsum rest, but not fully broken.

The disconnection was caused by disengagement of the top veneer layer from the bent plywood substrate which was located nether the arm balance with a section of veneer still fastened under the arm. It was a superficial and repairable intermission; while the rest of plywood vanquish was in good condition. Typical with chairs of this age, the veneered wooden frame of both chair and ottoman had scratches, chips on the edges, visible previous repairs, and slight discoloration. The dorsum veneered frame was darker than the seat frame, most likely caused by a variance in exposure to sunlight from an adjacent window. The metal risers of both the chair and ottoman had scratches and an uneven sheen. The upholstered seat and back cushions slightly lost their shape and support - visible by slightly sagging leather - which is typical from regular utilise.

Handling

Since the customer wanted to continue using the chair in the futurity, simply adhering the chair dorsum together at the arms was not an option since it would not guarantee that the interruption would non occur again, every bit the bond had been weakened. Hence, the chair was disassembled, and the disjointed parts were shipped to the manufacturer for structural treatment. Information technology was so assembled back together at Bernacki & Associates using hardware ordered from the manufacturer. The surface area of harm was retouched and integrated with the residuum of the chair. The metal risers were cleaned and polished. The leather upholstery was cleaned and conditioned.

These case studies reveal that even with a generally consequent design, a piece can sustain varying degrees of damage and require different approaches to treatment. At Bernacki & Associates each piece is individually assessed and treatment prescribed to best arrange the item too as the needs of the client.

Charles and Ray Eames set out to design a lounge chair that had the "warm receptive wait of a well-used beginning basemen's mitt". With the plush cushions, supple leather, contrasted with the contemporary plywood, metal base, along with the comfortable ergonomic design, they not only succeeded, they created an icon, one that is notwithstanding revered over 60 years later.

Practise yous have a challenging chair that could benefit from treatment? For more data contact:

info@bernackiconservation.com

0 Response to "Wood Lounge Chairs With Rounded Corners to the Arms by Restoration Hardware"

Post a Comment